HPC

- 4 1/2" (114.3 mm) thru 20" (508.0 mm)

- Single plug configuration

- Wrench style cap with 2" Figure 1502 hammer union fitting (tapered nose with O-ring seal)

- 2" Figure 1502 hammer union lifting plug with swivel shackle (for lifting cement head only)

- Operating wrench for cap and AQC nut

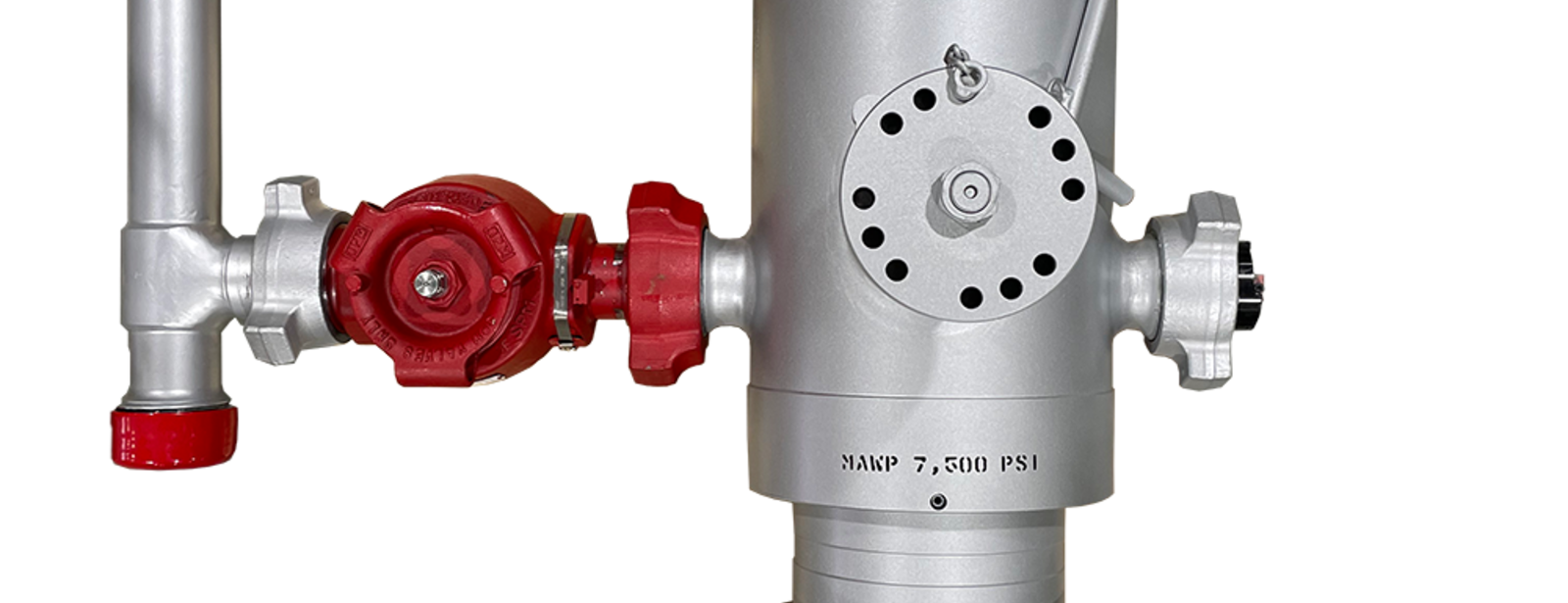

- Argus Quik-Connekt Adapter (AQC)

- Replaceable AQC bottom sub

- API SC casing pin standard on lower connection

- API LC or BC casing pin available on request

- Premium casing pin available on request

- Free-falling plug design

- Maximum plug OD = ØA – 1/4"

- Maximum plug OD = ØA – 1/4"

HPD

- 4 1/2" (114.3 mm) thru 20" (508.0 mm)

- Double plug configuration

- Wrench style cap with 2" Figure 1502 hammer union fitting (tapered nose with O-ring seal)

- 2" Figure 1502 hammer union lifting plug with swivel shackle (for lifting cement head only)

- Operating wrench for cap and AQC nut

- Argus Quik-Connekt Adapter (AQC)

- Replaceable AQC bottom sub

- API SC casing pin standard on lower connection

- API LC or BC casing pin available on request

- Premium casing pin available on request

- Free-falling plug design

- Maximum plug OD = ØA – 1/4"

- Maximum plug OD = ØA – 1/4"

DPA

- 3 1/2" (88.9 mm), 4" (101.6 mm) and 4 1/2" (114.3 mm)

- Single plug configuration

- Lifting sub with combination elevator shoulder (parallel nose with O-ring seal)

- Rotary lower swivel

- Replaceable bottom sub

- API rotary pin standard on lower connection

- Premium rotary pin available on request

- Customer shall specify rotary connection on purchase order

- Lift capacity is rated on the lifting sub and bottom sub configuration